Leak Down Test How To Perform A On A Engine

When the air is compressed into the cylinder, the leakdown tester will measure any loss of air escaping past valves or piston rings. A leak down test is a method of using compressed air and a specialized gauge set that reads differential pressure to evaluate the condition of an engine’s cylinders, pistons and rings, and valves and seats without disassembling the engine. If the cylinder is not at tdc, air escaping past an open valve will give a false reading.

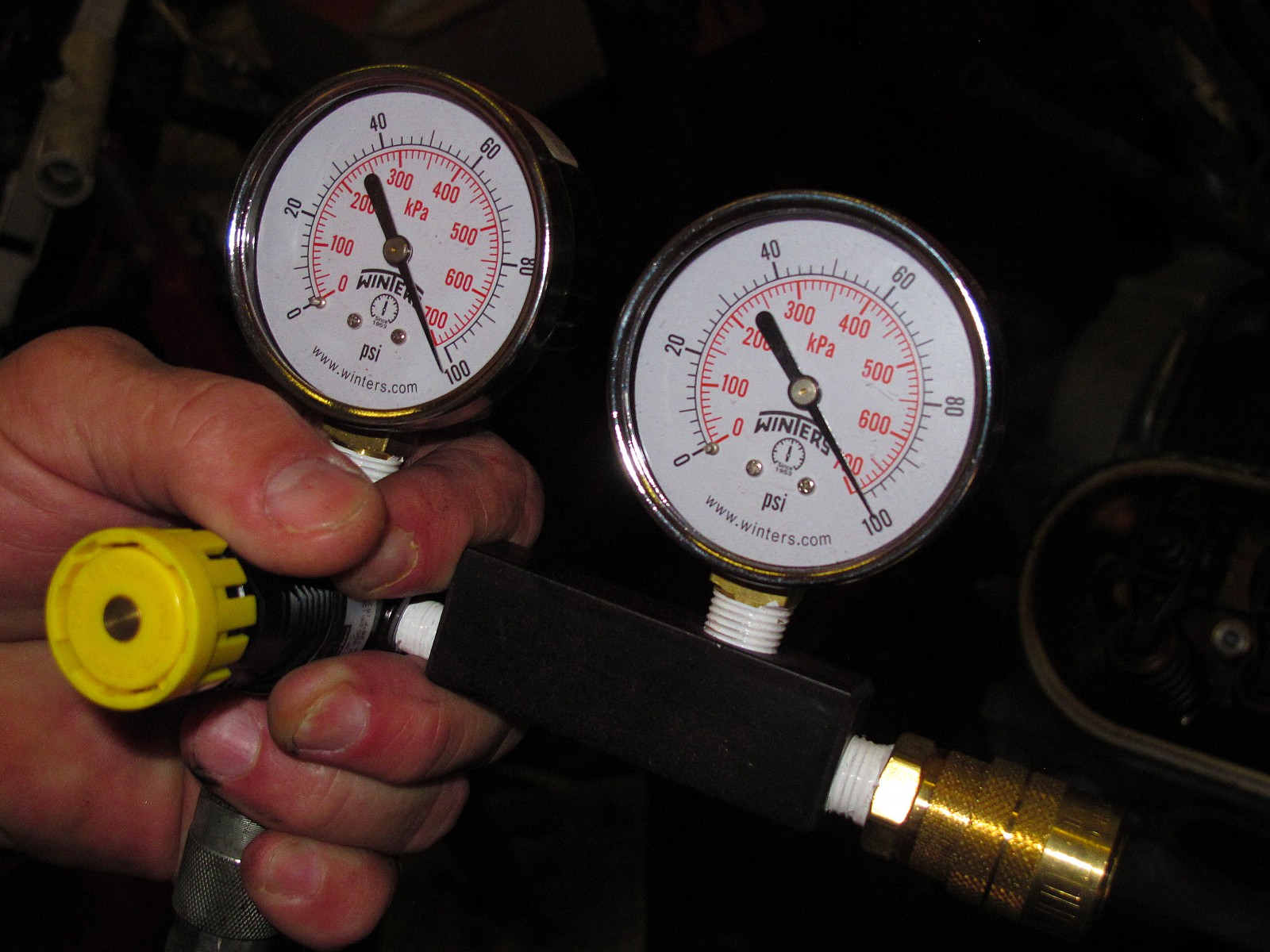

Cylinder Leak Down Tester,Compression Test Kit Engine Cylinder Dual

No engine will have perfect sealing with 0 percent loss. What is a leak down test? Cylinder pressure leak down tester.

In a cylinder leak down test the engine is placed on top dead centre (tdc), of the cylinder in question.

Then, using a similar type of connector as the compression test, we fill the cylinder with pressure. The tester then measures the volume of air needed to maintain, a predetermined pressure in the cylinder. Learn how to use a cylinder leakdown test to diagnose compression loss and pinpoint the source of the leak in an engine. What a leak down tester does, is compare the line pressure of an air source to the flowing pressure when the cylinder is pressurized.

The air source is connected to the tester and then the tester attached to the spark plug hole of the cylinder you are testing. A compression test uses the engine turning to generate the compression in the cylinder for the compression stroke, in which both intake and exhaust valves are closed. A leak down test uses a set of gauges and pressurizes the cylinder with air and measures how much of that air is escaping. The cylinder leak down test is an advanced form of the compression test, providing more detailed and accurate information about the condition of an engine.

A leak down test grants a deeper understanding by revealing where compression is being lost within an engine.

When the air is compressed into the cylinder, the leakdown tester will measure any loss of air escaping past valves or piston rings. If the cylinder is not at tdc, air escaping past an open valve will give a false reading. No engine will have perfect sealing with 0 percent loss. A cylinder leak down test or cylinder leakage test, is actually similar to a compression test:

So, a compression test measures, how well your engine’s cylinders are sealing. But, a cylinder leak down test, takes it to the next level and measures, cylinder pressure loss. A cylinder leak down test helps me assess internal engine health, isolate failing cylinders, and determine whether an engine needs a simple fix or a full rebuild. It’s especially helpful in cases where an engine is overheating, and i can’t pinpoint the root cause.

What is a leak down test?

A leak down test is a method of using compressed air and a specialized gauge set that reads differential pressure to evaluate the condition of an engine’s cylinders, pistons and rings, and valves and seats without disassembling the engine. A compression test uses the engine turning to generate the compression in the cylinder for the compression stroke, in which both intake and exhaust valves are closed. A leak down test uses a set of gauges and pressurizes the cylinder with air and measures how much of that air is escaping. The leakdown tester is a great diagnostic tool to identify real cylinder pressure difficulties.

But don’t be alarmed if you get 15 to 18 percent leakdown on all cylinders. What a leak down tester does, is compare the line pressure of an air source to the flowing pressure when the cylinder is pressurized. The air source is connected to the tester and then the tester attached to the spark plug hole of the cylinder you are testing. Today, it's common practice to use a cylinder leak down gauge to evaluate how well each cylinder performs in retaining pressure.

The process is simple enough:

Pump a measured amount of air 2006 model subaru when warm noticeable misfire at idle, computer is picking up cylinder number two misfire fault, did depression test on that cylinder just to eliminate obvious bad failure, which compression was fine, put leak down tester on top that center and got decent results. 95 psi in 70 psi out, did the cylinder next to it, cylinder number four, got 95 psi in and 35 psi out, verified Key points for a successful engine cylinder leak down test.

This test will allow you to pinpoint internal engine issues… misfires, excessive oil consumption, and power loss are a few of the primary culprits. A few key tips to help you perform an engine cylinder In this video i show how to accurately perform a cylinder leak down test. This test pinpoints faults causing that cause low compression on your engine, it gi

If you have done a cranking compression test and have identified one or more cylinders that are much lower than the rest, you can do another test to find out the cause.

In contrast, to the cylinder leak down test, which measures how much pressure, is lost in the engine. Cylinder pressure leak down tester. In a cylinder leak down test the engine is placed on top dead centre (tdc), of the cylinder in question. Then, using a similar type of connector as the compression test, we fill the cylinder with pressure.

I don’t often use an actual leak down tester when doing this test. In fact, i do a compression test and look for a problem cylinder, and if i find it, i take a little short cut. You can actually use your compression tester hose for leak down testing. You first have to remove the schrader valve in the compression tester hose.

Combining the results of a leak down test with a cranking compression test can indicate an engine's potential.

For a street engine, cranking pressure between 175 and 200 psi is ideal. The cylinder leak down test is an advanced form of the compression test, providing more detailed and accurate information about the condition of an engine. A leak down test grants a deeper understanding by revealing where compression is being lost within an engine. When the air is compressed into the cylinder, the leakdown tester will measure any loss of air escaping past valves or piston rings.

If the cylinder is not at tdc, air escaping past an open valve will give a false reading. No engine will have perfect sealing with 0 percent loss. A cylinder leak down test or cylinder leakage test, is actually similar to a compression test: So, a compression test measures, how well your engine’s cylinders are sealing.

But, a cylinder leak down test, takes it to the next level and measures, cylinder pressure loss.

Cylinder pressure leak down tester. In a cylinder leak down test the engine is placed on top dead centre (tdc), of the cylinder in question. Then, using a similar type of connector as the compression test, we fill the cylinder with pressure. The tester then measures the volume of air needed to maintain, a predetermined pressure in the cylinder.

A cylinder leak down test helps me assess internal engine health, isolate failing cylinders, and determine whether an engine needs a simple fix or a full rebuild. It’s especially helpful in cases where an engine is overheating, and i can’t pinpoint the root cause.